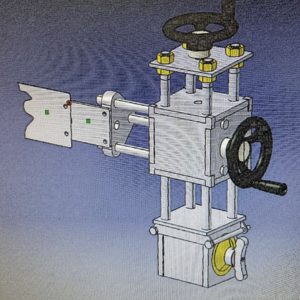

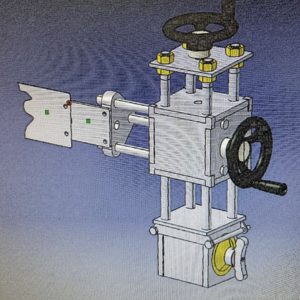

Description of the New Pottery Forming Device

The wheel-shaped handle at the top adjusts the vertical position of the forming blade, while the centrally placed wheel-shaped handle moves the blade forward and backward. This allows the forming blade to gradually shave down the clay that has been placed over the plaster mold positioned at the center of the potter’s wheel.

With this process, the clay vessel requires no separate trimming of its exterior and can proceed directly to drying. At the same time, conventional foot trimming can also be completed within this process. Depending on the shape of the forming blade, highly detailed and refined exterior trimming can be achieved with precision.

This device can be mounted on any part of a standard cast-iron electric wheel body, and the operator may position it wherever convenient. It is held securely in place by a powerful magnet for ease of use.

Important Note on Usage

This device requires that the upper part of the plaster mold be at least slightly narrower than the lower part (a conical form). Only then can the vessel be easily released from the mold after trimming. In other words, the device is limited to vessels whose interiors follow a simple vertical line. However, for design purposes, once the exterior trimming is complete, the clay can still be reshaped—for example, narrowing the top or widening the bottom to achieve a reverse-conical form (narrow above, broad below).